Advanced Vibro Technology

Knowledge through Experience

Thanks to the active involvement of our people and customers, PVE Equipment USA has a peerless knowledge and expertise regarding today’s advanced vibro technology. For years, we listened and learned. Using that experience, we have been developing and supplying hundreds of vibratory hammers and power packs ever since. Our vibratory hammers are excellent in both cold and hot conditions. Our vibro technology enables us to deliver sustainable, inventive products with such features as:

- vibratory hammers and power packs with vast hydraulic power

- advanced oil lubrication to withstand temperatures between -40 f and 122 f, onshore and offshore

- computer-driven iQan motor management with options such as GPRS tracking and remote monitoring

Technology

When to Use Hydraulic Vibratory Hammers

Our vibratory hammers are used for a wide variety of projects. Apart from driving and extracting elements such as sheet piles and pipes, vibratory hammers are also used for soil densifying or vertical drainage. With our vibro technology it is possible to drive offshore at a depth of 800 feet under water for the driving of casings for gas and oil pipe lines.

A vibratory hammer drives elements into the soil through the centrifugal force of its eccentric weights. Vibratory technology is easier than most conventional technologies, and it also cuts down operating time and costs.

What Type of Hammer?

The proper hydraulic vibratory hammer to use on the job site depends on:

- size, dimensions, and weight of the elements to be driven

- soil conditions at the site

- presence of construction close to the site

Principle of a Vibratory Hammer

Elements are driven into the soil by generating vibrations in the adjacent soil particles in order to reduce the natural resistance. Depending on the technology used, these vibrations may vary from a limited spread to a perimeter of kilometers.

The dynamic weight of a hydraulic hammer or pile driver produces a high pulsating load at a low frequency. With a vibratory hammer, the opposite will occur: a relatively low steady load at a high frequency. Thanks to the low impact of the vibratory hammer, the risk of fractures and cracks is eliminated.

A vibratory hammer is used to drive sheet piles, pipes, or other elements into the soil by vertical vibrations. The adjacent soil particles are put into motion and thus the soil is loosened. The dynamic weight of the hammer will drive the elements into the soil (before extracting is done with a crane).

VM Technology

Conventional vibratory hammers have a constant eccentric moment. When passing the critical frequency area during start-up and stop, the constant amplitude will cause disturbing negative vibrations in the boom of the crane and in the soil—not just at the spot, but within a considerable perimeter. Our vibratory hammers with variable moment (VM) technology, however, produce excellent results and can even operate safely next to buildings.

Driving in Urban Areas

The high frequency (HF) vibratory hammers generate vibrations at a rev of 2,000 to 2,300 rpm. Compared to a low frequency vibratory hammer, a HF hammer produces less vibration in the nearby surroundings. Tests have demonstrated that the vibration level of a HF hammer—measured at a distance of 6 feet from the driving element—equals the level of vibrations produced by a low frequency hammer at a distance of 48 feet.

When using a high-frequency vibratory hammer with an adjustable moment of 0 to the maximum 2,300 revolutions per minute, critical vibrations in start-up and stop are eliminated. After passing the critical frequency area, the eccentric weights are automatically adjusted and synchronized to the current eccentric moment. Therefore, when driving in urban areas, it is best to use a vibratory hammer with variable moment.

The process works as follows:

During the start-up of the vibratory hammer, before it approaches the maximum frequency of 2,300 revolutions per minute, the eccentric moment is 0. The eccentric weights cancel each other out and no vibrations (amplitude) are generated. While approaching the maximum frequency, the automatic adjustment of the eccentric weights takes place: the so-called in-moment amplitude. As the vibratory hammer nears its maximum frequency, there is no question of passing a critical frequency. Disturbing vibrations during start-up and stop are eliminated.

The adjustment of the eccentric weights is completely automated. As manual (remote) control for shifting the eccentric weights is possible, the most ideal amplitude can be generated for each soil type.

It is not necessary to readjust the vibratory hammer when stopped and restarted. The hammer will automatically select the last setting. With VM, it is possible to maintain the hammer at its maximum frequency while bringing the eccentric moment to 0. The hammer can be brought to a standstill without causing any vibrations.

VM works automatically and safely, so it is an ideal alternative to the pressing method.

Principle of Pile Foundations

A pile foundation is necessary when the loads of a building will be higher than the upper soil layer can take. Piles are installed primarily to avoid settlements, which could result in major damages and dangerous situations. In a limited number of projects, piles are installed as tension piles. These are installed to prevent the object from lifting out of the ground. A well-known example is the piles installed under high-tension electricity piles. Due to high forces created by wind, the piles need to be anchored in the ground.

Soil Type versus Pile Type

There are many different piles and piling methods. Some of the methods are very efficient in the weaker soils, but can’t be executed in hard soils. In some cases—for example, when building a skyscraper—it is necessary to install piles into hard rock as well. The methods for this are rather limited.

Soil investigation

To come to the best design for a pile foundation, it is absolutely necessary to have a good soil report and investigation on the ground conditions where the job site will be. A good report and inspection will minimize the risk of unexpected delay and additional costs. Our company does not supply soil investigation equipment, but for the vibratory and impact hammers there are special prediction programs available (WEAP), which can help to determine the drivability of certain sheet piles and casings in different ground conditions.

Pile driving

Precast concrete piles, steel tubes, H-beams (with or without grout injection) cast in situ are common materials in pile driving. In this system, a casing with temporary bottom plate is driven into the ground. When reaching the required level of reinforcement, a steel cage consisting of some small bars is lowered into the casing and fresh concrete is poured or pumped in the casing. After concreting, the casing is extracted again to be used again in the same principle. We are specialists in this field and have many different machines for this.

Drilling Rigs

The purpose-built rigs of Woltman are able to operate in many drilling configurations, such as:

- Semi-Displacement Drilling

- CFA Drilling

- Full-Displacement Drilling

- Double-Rotary Drilling

Semi-Displacement Piles

With semi-displacement piles, a combination of CFA and displacement is used. The center of the auger is much wider, which creates a larger displacement movement than a normal auger would do. Still, it has the spirals on the side, which creates the upward movement of the soil. This pile is mostly used when the soil is too weak for a normal CFA pile.

CFA Drilling

Continuous Flight Auger (CFA) piles are installed by screwing an auger into the ground. During this process, soil is moved upwards by the spirals of the auger. After reaching the desired depth, concrete is pumped through the center pipe while the auger is being extracted. The same auger can be used to install multiple piles. When the auger is extracted from the hole, the ground crew will put the reinforcement in. This method is very fast, but pile loads are limited because the piles are not reinforced over the full length. Woltman offers multiple machines for CFA operation.

Displacement Drilling

This method is used for weaker soil conditions. The piles made according this drilling system have a higher bearing capacity compared to the CFA piles because no soil is moved upwards, but the soil is pushed to the side, and so will be compacted (displaced). Because of the compaction of the soil, a bigger and stronger machine is required compared to CFA drilling. In some cases, the contractor simply prefers not to take soil out of the ground. A perfect example is soil which used to belong to a chemical factory or oil refineries. Displacement drilling piles are becoming more and more popular in the USA. Thanks to the soil in Holland, we have already more than 15 years’ experience with soil displacement drilling. Therefore the rigs that Woltman has to offer for this type of drilling are exceptionally well-developed.

Double-Rotary Drilling

Double rotary drilling is a method in which a casing and auger are drilled into the ground simultaneously with the help of double rotary heads. In most cases, this is performed to install a pile wall (for example, as a wall in an underground parking garage, or a wall towards a tunnel).

Contact us when your project calls for high-performance drilling equipment. Our company proudly serves clients throughout the nation and offers global support solutions.

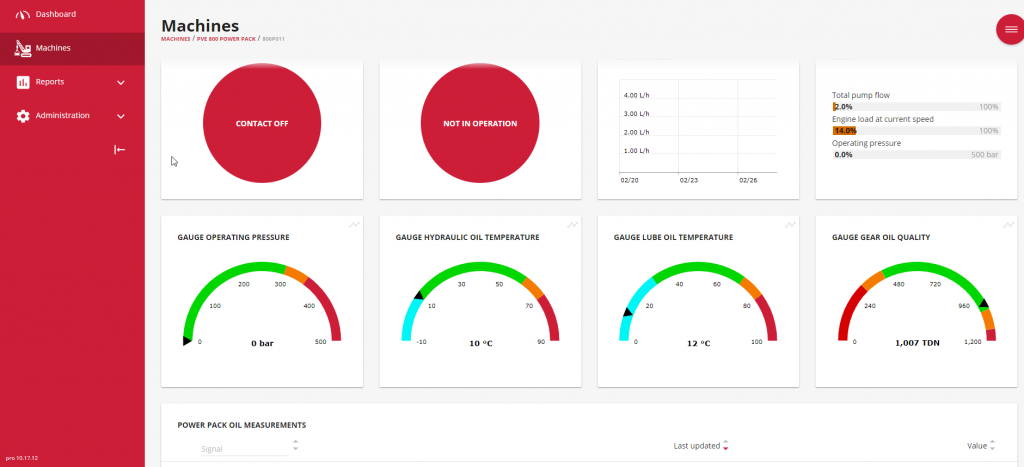

PVE Power Pack Monitoring System

A newly integrated feature of our power packs is an interactive monitoring system. This PVE monitoring system is unique in that it can be accessed anywhere via an internet connection. The monitoring system can analyze and report an unlimited amount of power packs due to the portal technology. With just an internet connection all power packs connected to the system can be monitored for maintenance, optimization and analyses. The worldwide connection to PVE power packs reduces downtime, accelerates trouble shooting, and ensures customer satisfaction.