Products

PVE, short for Piling and Vibro Equipment, delivers the advanced technology and dependable performance contractors need for complex foundation work. Whether your project is across town or across the country, we offer sales, rentals, and expert support to help keep your job on track.

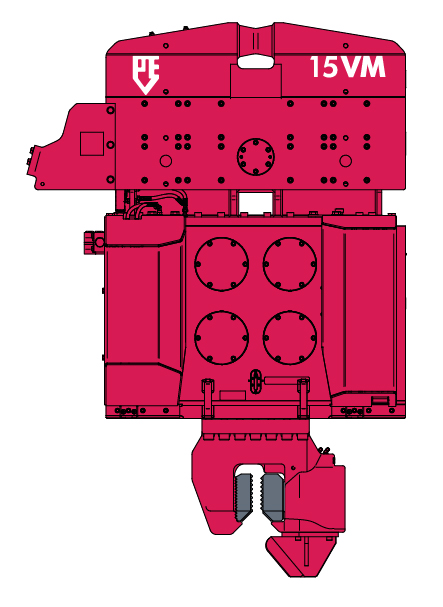

Our patented high-frequency Variable Moment (VM) vibratory hammers are trusted around the world and have become a go-to solution for contractors across the U.S. The VM system offers unmatched control, power, and safety, especially in sensitive environments.

If you don’t see the equipment you’re looking for, contact our team. We’re here to help you find the right solution for your specific job site needs.

| Picture | ID | Vibratory Hammer Type | Eccentric Moment | Max. Centrifugal Force |

|---|---|---|---|---|

| PVE 12VM | Variable Moment | 0 - 1,040 Inch-Lbs. | 0 - 80 Tons |

| PVE 15VM | Variable Moment | 0 - 1,390 Inch-Lbs. | 0 - 105 Tons |

| PVE 16VM | Variable Moment | 0 - 1,390 Inch-Lbs. | 0 - 105 Tons |

| PVE 20VM | Variable Moment | 0 - 1,650 Inch-Lbs. | 0 - 125 Tons |

| PVE 23VML | Variable Moment | 0 - 1,997 Inch-Lbs. | 0 - 159 Tons |

| PVE 24VM | Variable Moment | 0 - 2,085 Inch-Lbs. | 0 - 155 Tons |

| PVE 28VM | Variable Moment | 0 - 2,430 Inch-Lbs. | 0 - 180 Tons |

| PVE 35VM | Variable Moment | 0 - 3,040 Inch-Lbs. | 0 - 228 Tons |

| PVE 40VM | Variable Moment | 0 - 3,470 Inch-Lbs. | 0 - 198 Tons |

| PVE 50VM | Variable Moment | 0 - 4,340 Inch-Lbs. | 0 - 326 Tons |

| PVE 70VM | Variable Moment | 0 - 6,075 Inch-Lbs. | 0 - 345 Tons |

| PVE 90VM | Variable Moment | 0 - 7,813 Inch-Lbs. | 0 - 503 Tons |

PVE’s standard frequency vibratory hammers are trusted by contractors worldwide for their strength, durability, and consistent performance. Built with advanced technology and regularly updated for today’s job site demands, these hammers are ideal for projects that require dependable, efficient operation.

Below is our current product range available in the U.S. If you’re looking for a specific model or custom configuration not listed here, please contact us to explore additional options.

| Picture | ID | Vibratory Hammer Type | Eccentric Moment | Max. Centrifugal Force |

|---|---|---|---|---|

| PVE 23M | Normal Frequency | 2,000 Inch-Lbs. | 73.5 Tons |

| 2020 PVE 33M - PVE 33M | Normal Frequency | 2,900 Inch-Lbs. | 118 Tons |

| PVE 55M | Normal Frequency | 4,690 Inch-Lbs. | 192 Tons |

| PVE 82M | Normal Frequency | 7,030 Inch-Lbs. | 288 Tons |

| PVE 110M | Normal Frequency | 9,550 Inch-Lbs. | 247 Tons |

| PVE 150M | Normal Frequency | 13,019 Inch-Lbs. | 362 Tons |

| PVE 200M | Normal Frequency | 17,359 Inch-Lbs. | 483 Tons |

| PVE 250M | Normal Frequency | 21,699 Inch-Lbs. | 604 Tons |

| PVE 300M | Normal Frequency | 26,038 Inch-Lbs. | 691 Tons |

| PVE 500M | Normal Frequency | 43,398 Inch-Lbs. | 1,208 Tons |

PVE’s excavator-mounted vibratory hammers are the result of over 30 years of engineering and field-tested durability. Designed for flexibility and ease of use, these compact units offer reliable performance in tight spaces and demanding conditions.

With a broad selection available, it’s easy to find the right match for your excavator and project requirements. If you don’t see the model you need, contact us to discuss additional options.

| Picture | ID | Vibratory Hammer Type | Eccentric Moment | Max. Centrifugal Force |

|---|---|---|---|---|

| PVE 2803 | High Frequency | 278 Inch-Lbs. | 31 Tons |

| PVE 2804 | High Frequency | 399 Inch-Lbs. | 44 Tons |

| PVE 2506 | High Frequency | 521 Inch-Lbs. | 46 Tons |

| PVE 2308 | High Frequency | 695 Inch-Lbs. | 49 Tons |

| PVE 2312 | High Frequency | 998 Inch-Lbs. | 75 Tons |

| PVE 6VMA | Variable Moment | 564 Inch-Lbs. | 42 Tons |

| PVE 8VMA | Variable Moment | 651 Inch-Lbs. | 49 Tons |

| PVE 12VMA | Variable Moment | 1,041 Inch-Lbs. | 79 Tons |

| PVE 23VMA | Variable Moment | 2,000 Inch-Lbs. | 135 Tons |

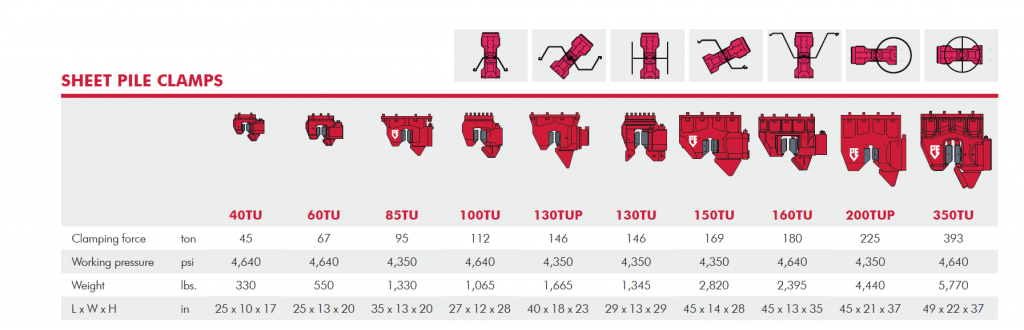

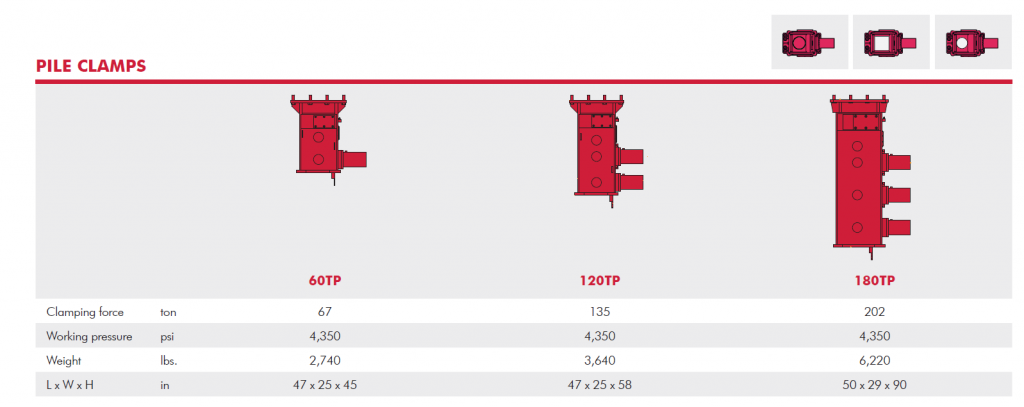

PVE offers a full range of robust clamping systems, beams, and cross beams designed to handle sheet piles, tubular piles, concrete piles, and even wooden piles. Each clamp is built for reliable performance under demanding site conditions.

Need help selecting the right clamp? Our team is ready to recommend the best solution for your equipment and application.

PVE power packs are equipped with top-brand engines and hydraulic pumps, built to meet Tier 4 Final emissions standards and modern job site requirements.

PVE power packs are compatible with a wide range of equipment.

Marine foundation work demands reliable, high-performance machinery. PVE offshore solutions are purpose-built to withstand extreme weather, pressure, and exposure while delivering consistent results.

From wind farm foundations to oil and gas infrastructure, our vibro technology provides an efficient and environmentally responsible solution. It minimizes underwater noise and disruption to marine life while meeting the industry’s most stringent environmental standards.

Our offshore equipment is backed by expert support and 24/7 response teams to keep your project moving, no matter the conditions.

Vibro compaction is used to increase the density of loose, granular soils containing less than 10–15% silt. A vibroflot penetrates the soil with the help of high-pressure water jets, vibration, and saturation. The result is a more compact, stable foundation layer.

Optional extension tubes are available for compaction at depths beyond 80 feet.